Triumph Street Triple S - Service manual > Electrical Connectors

Triumph Street Triple S - Service manual > Electrical Connectors

Before beginning any diagnosis, the following connector related information should be noted:

Note:

- A major cause of hidden electrical faults can be traced to faulty electrical connectors. For example:

- Dirty/corroded terminals.

- Damp terminals.

- Broken or bent cable pins within multi-plugs.

For example, the electronic control module (ECM) relies on the supply of accurate information to enable it to plan the correct fueling and ignition timing. One dirty terminal will cause an excessive voltage drop resulting in an incorrect signal to the ECM.

If, when carrying out fault diagnosis, a fault appears to clear by simply disconnecting and reconnecting an electrical plug, examine each disconnected plug for the following.

Before Disconnection:

- If testing with a voltmeter, the voltage across a connector should be virtually battery volts (unless a resistor is fitted in the circuit). If there is a noticeable change, suspect faulty/dirty connections.

When Disconnecting a Connector:

- Check for a security device that must be released before the connector can be separated. E.G. barb, hook and eye etc.

When Inspecting a Connector:

- Check that the individual pins have not been bent.

- Check for dampness/dirt/corrosion.

- Check cables for security.

- Check cable pin joints for damage.

When Connecting a Connector:

- Ensure there is no dirt around the connector/seal.

- Push together squarely to ensure terminals are not bent or incorrectly located.

- Push the two halves together positively.

Disconnection of ECM connectors

Note:

- Two different coloured and shaped connectors are used in the

ECM, which ensures correct connection is always made.

The connectors on the ECM are coloured black and grey, and correspond with identical coloured connectors on the main harness.

Caution: When disconnecting a connector, never pull directly on the wires as this may result in cable and connector damage.

Caution: Never disconnect the ECM when the ignition switch is in the 'ON' position as this may cause multiple fault codes to be logged in the ECM memory.

Always disconnect an ECM after disconnecting the battery negative (black) lead first.

1. Turn the ignition to the 'OFF' position and wait at least 1 minute for the ECM to complete its power down sequence.

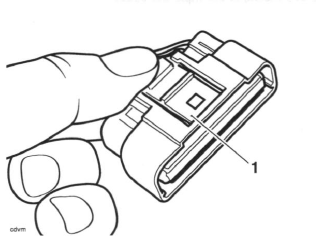

2. Press down on the locking device and gently pull back on the connector to release it from the ECM.

- Locking device

Note:

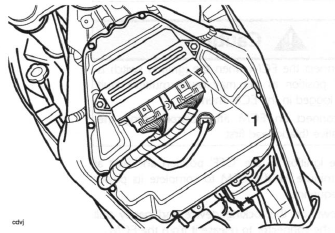

- The ECM is located beneath the fuel tank, on the upper section of the airbox.

Reconnection of ECM connectors

Note:

- Two different coloured and shaped connectors are used in the

ECM, which ensures correct connection is always made.

The connectors on the ECM are coloured black and grey, and correspond with identical coloured connectors on the main harness.

Caution: Damage to the connector pins may result if an attempt to fit the connectors incorrectly is made.

- ECM (Daytona 675 shown, Street Triple and Street Triple R similar)

1. Fit the first connector into its socket and, whilst holding the connector in place, insert it fully into the ECM until the locking device retains it.

2. Repeat the above for the second connector.

Further Diagnosis

The tables that follow will, if used correctly, help to pinpoint a fault in the system once a diagnostic trouble code has been stored.

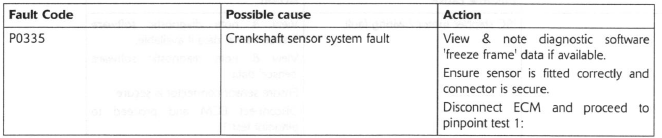

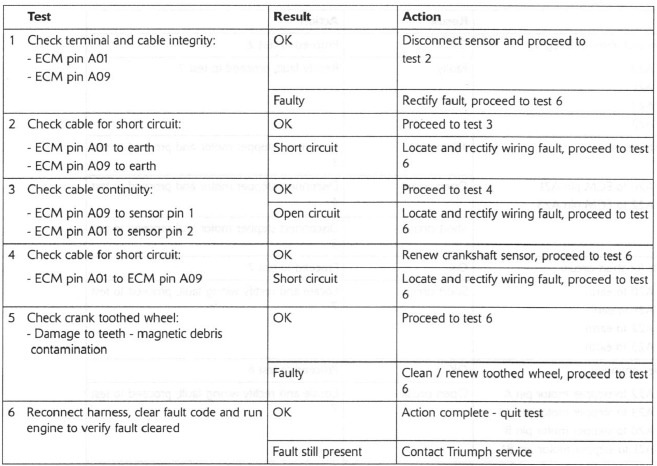

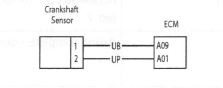

Crankshaft Sensor

Pinpoint Tests

Circuit Diagram

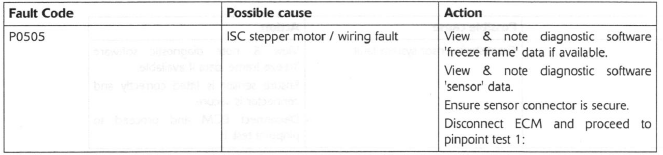

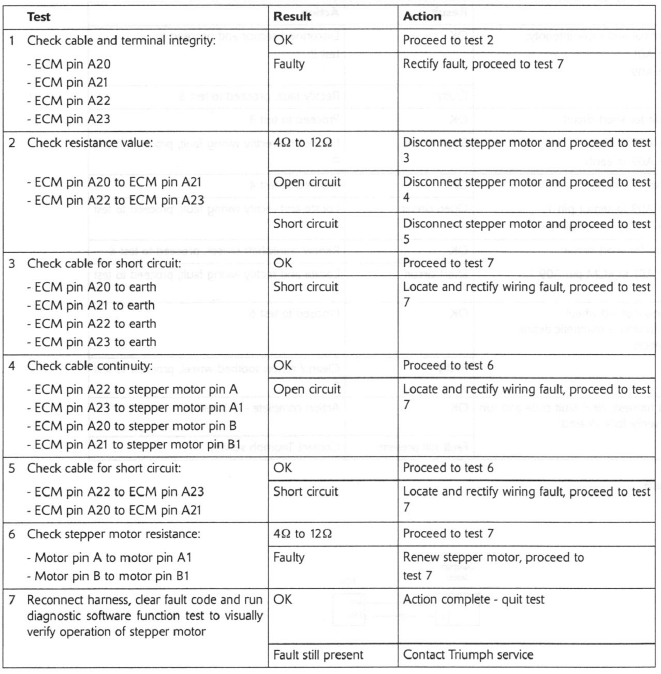

Idle Speed Control

Pinpoint Tests

Circuit Diagram

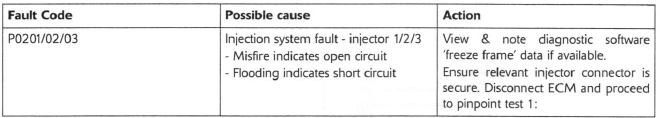

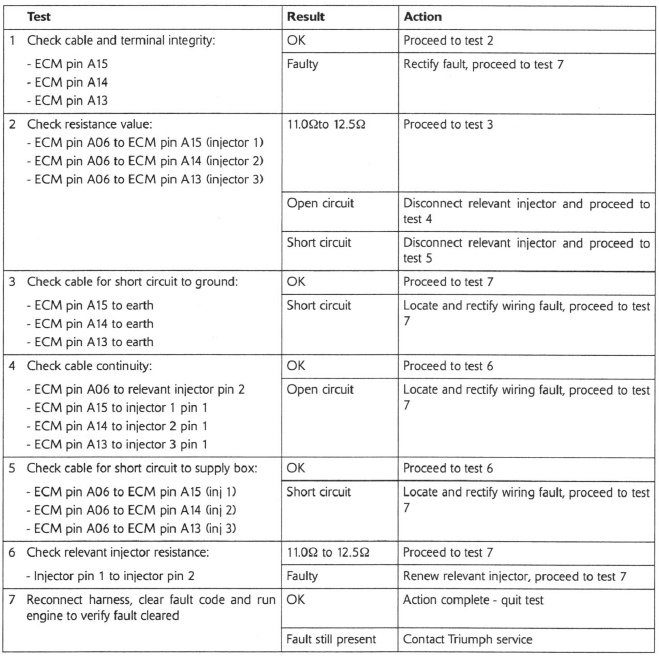

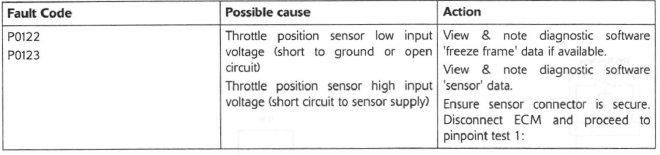

Fuel Injectors

Pinpoint Tests

Circuit Diagram

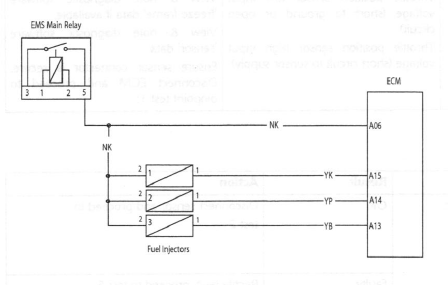

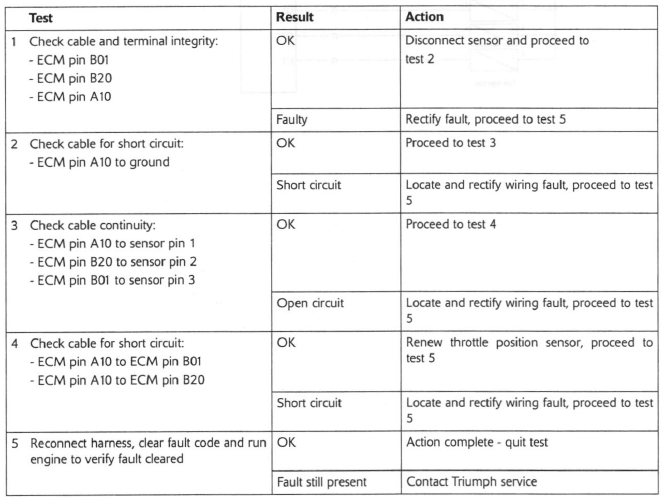

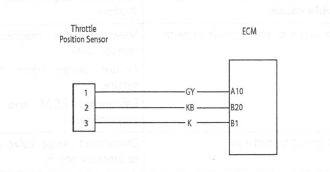

Throttle Position Sensor

Pinpoint Tests

Circuit Diagram

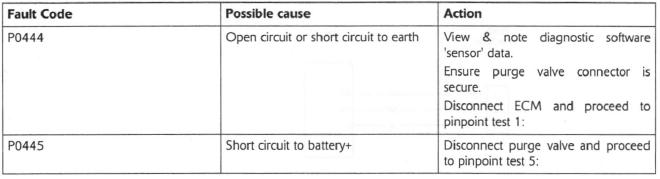

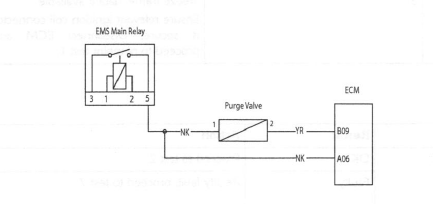

Purge Valve

Pinpoint Tests

Circuit Diagram

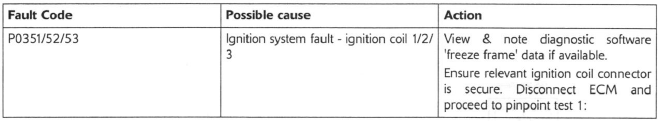

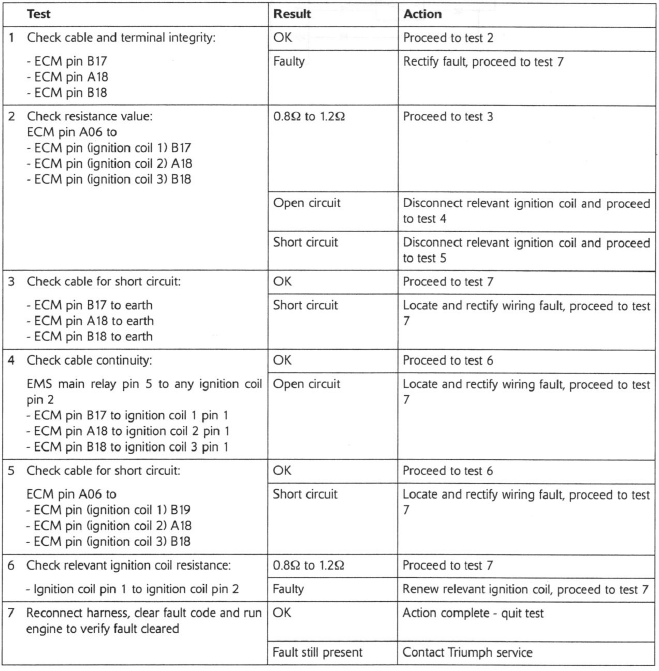

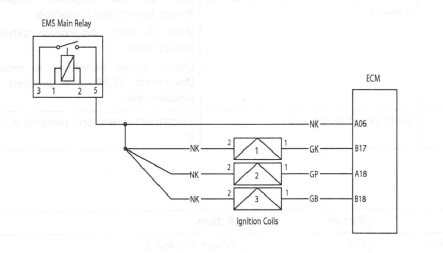

Ignition Coils

Pinpoint Tests

Circuit Diagram

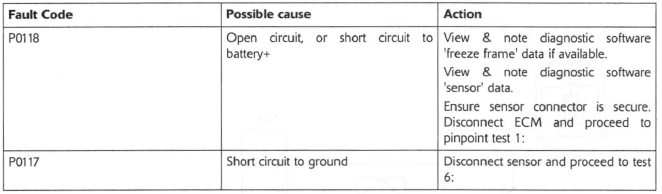

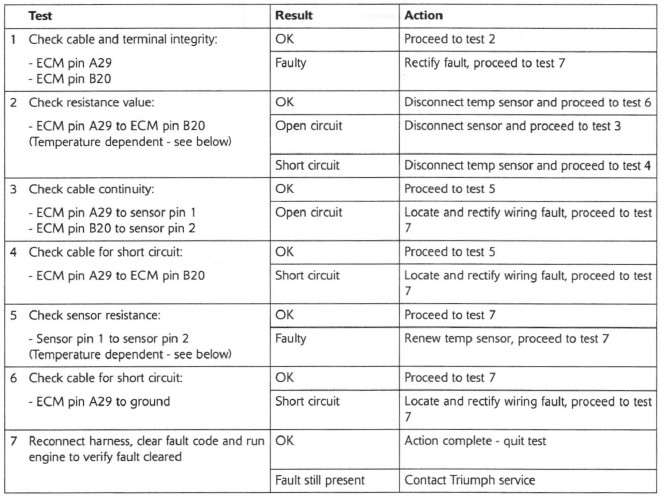

Coolant Temperature Sensor

Pinpoint Tests

Circuit Diagram

Resistance data under typical conditions:

Warm engine: 200 to 400Ω

Cold engine:

20ºC ambient 2.35 to 2.65KΩ

-10ºC ambient 8.50 to 10.25KΩ

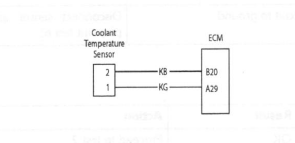

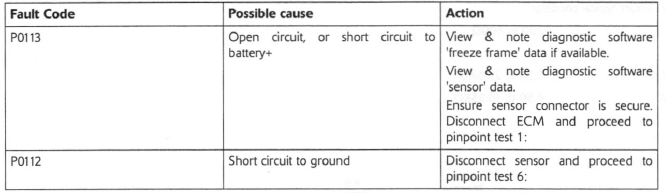

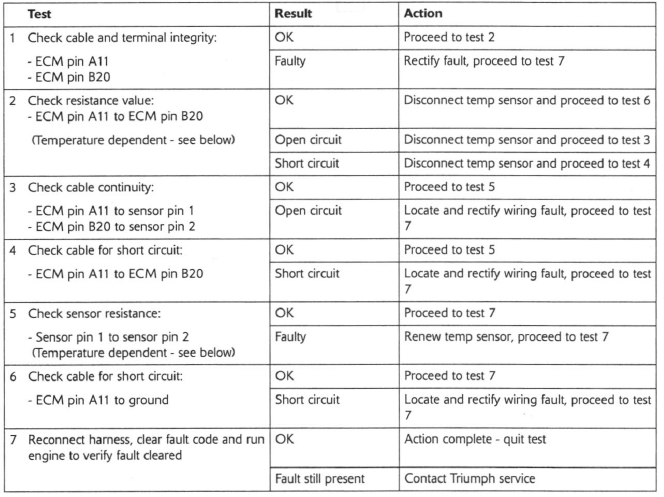

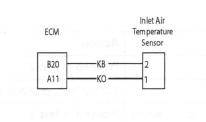

Intake Air Temperature Sensor

Pinpoint Tests

Circuit Diagram

If engine is warm, remove sensor and allow time to cool to ambient prior to test.

Resistance data:

Ambient temp Resistance value

80ºC 200 to 400Ω

20ºC 2.35 to 2.65KΩ

-10ºC 8.50 to 10.25KΩ

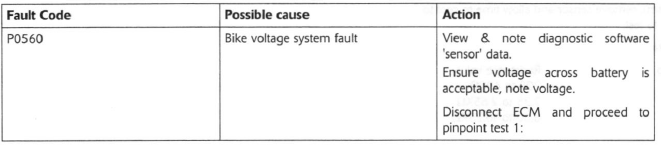

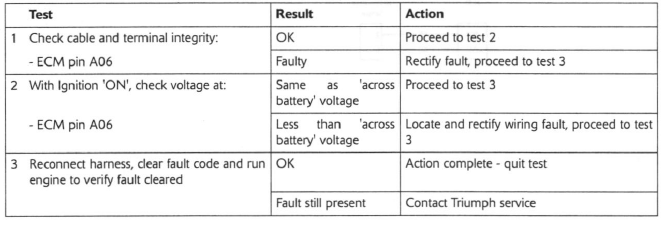

System Voltage

Pinpoint Tests

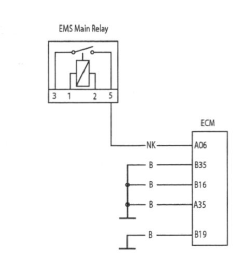

Circuit Diagram

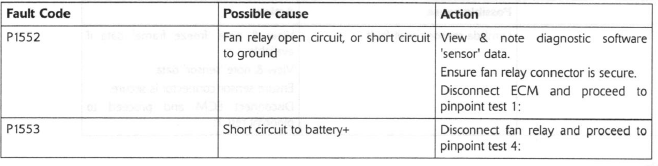

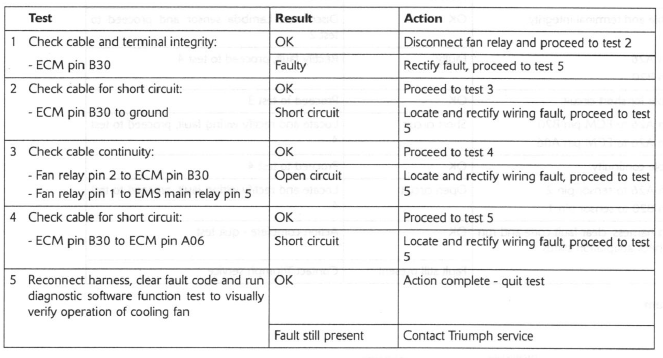

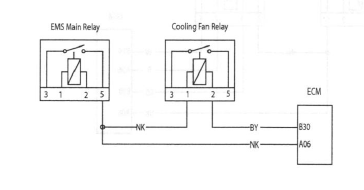

Cooling Fan Relay

Pinpoint Tests

Circuit Diagram

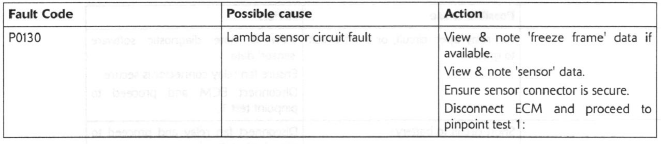

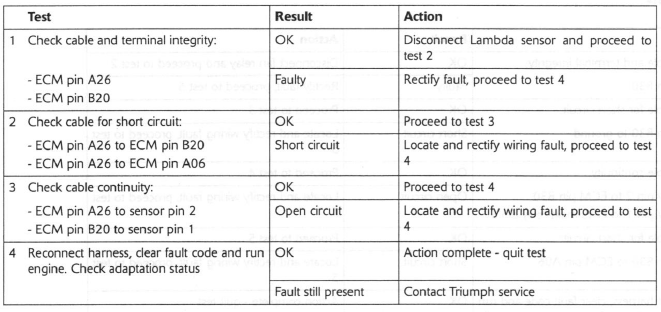

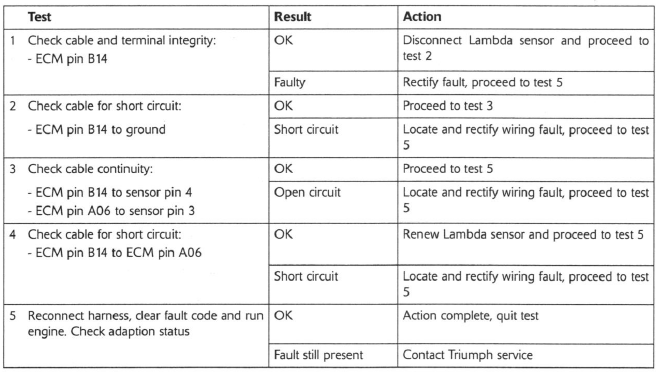

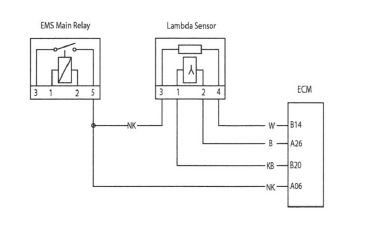

Lambda Sensor

Pinpoint Tests

Circuit Diagram

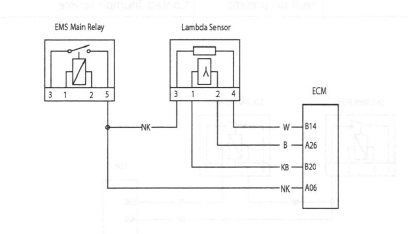

Lambda Sensor Heater

Pinpoint Tests

Circuit Diagram

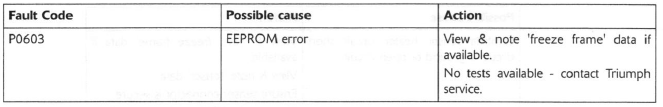

EEPROM Error

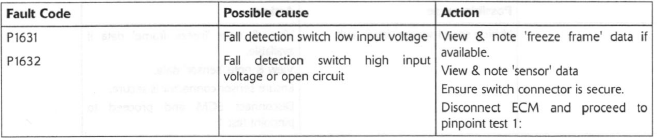

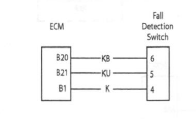

Fall Detection Switch

Pinpoint Tests

Circuit Diagram

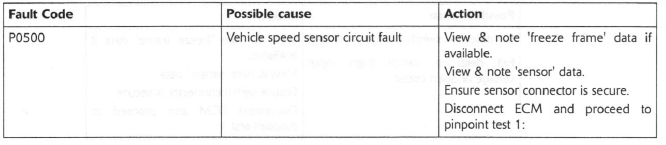

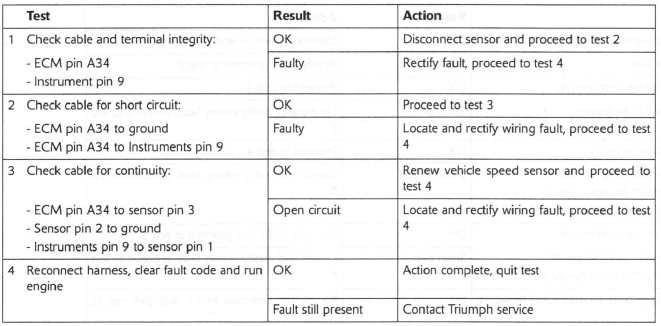

Vehicle Speed Sensor

Pinpoint Tests

Circuit Diagram

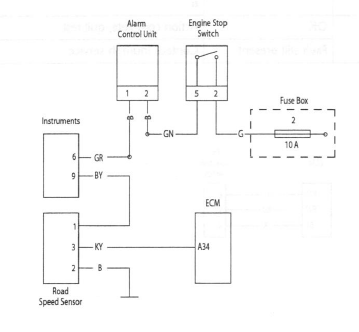

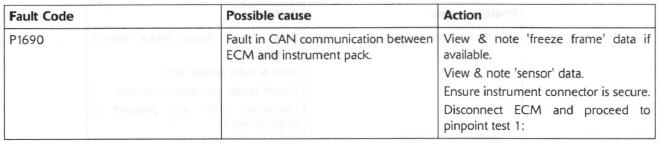

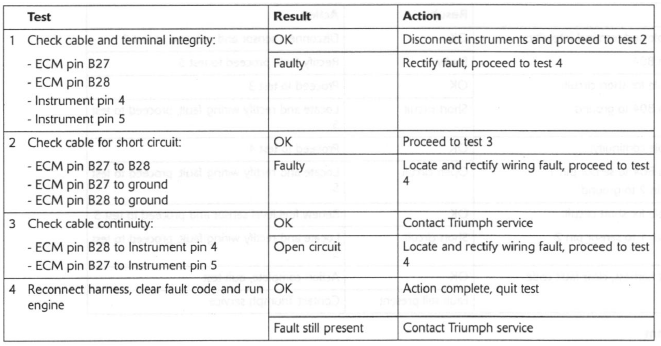

Instrument Communication (CAN)

Pinpoint Tests

Circuit Diagram

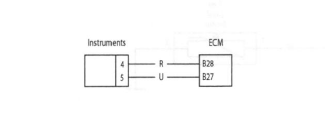

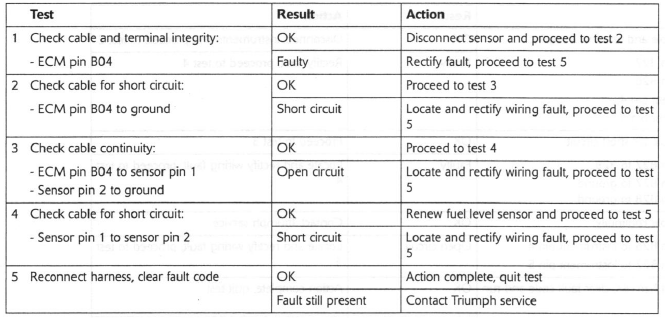

Fuel Level Sensor

Pinpoint Tests

Circuit Diagram

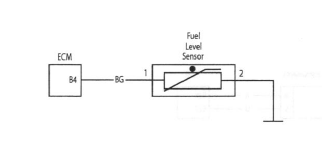

Ambient (Barometric) Pressure Sensor

Pinpoint Tests

Circuit Diagram

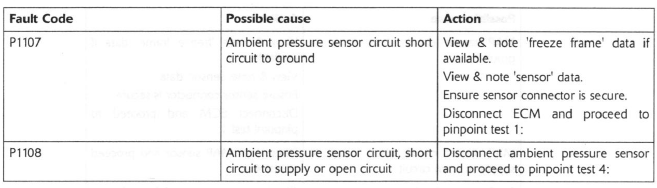

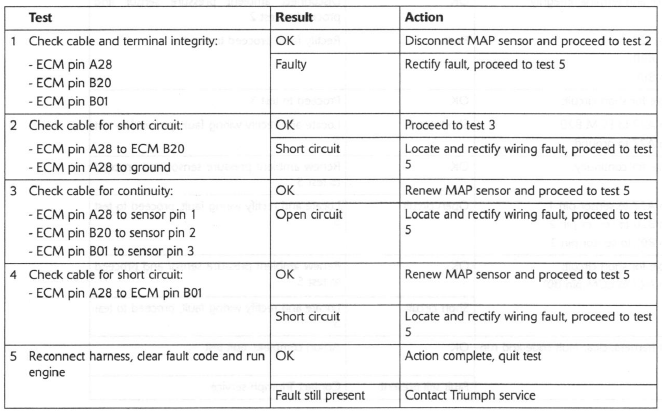

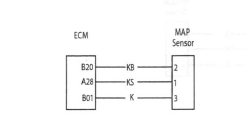

Manifold Absolute Pressure (Map) Sensor

Pinpoint Tests

Circuit Diagram

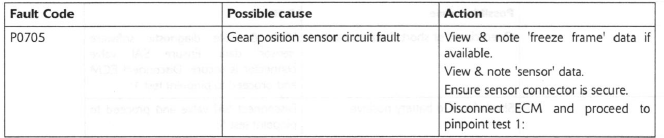

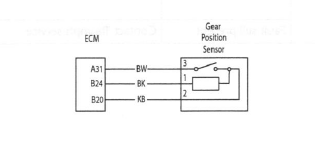

Gear Position Sensor

Pinpoint Tests

Circuit Diagram

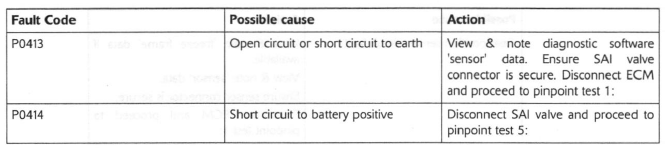

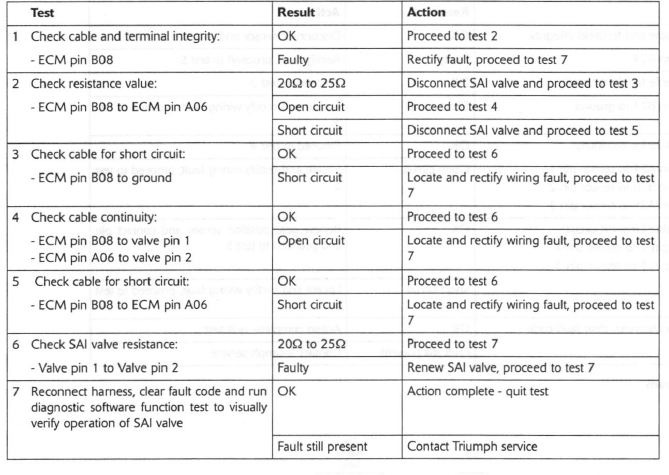

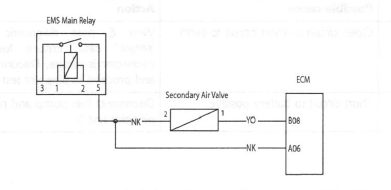

Secondary Air Injection Valve

Pinpoint Tests

Circuit Diagram

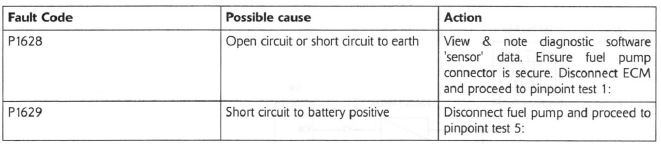

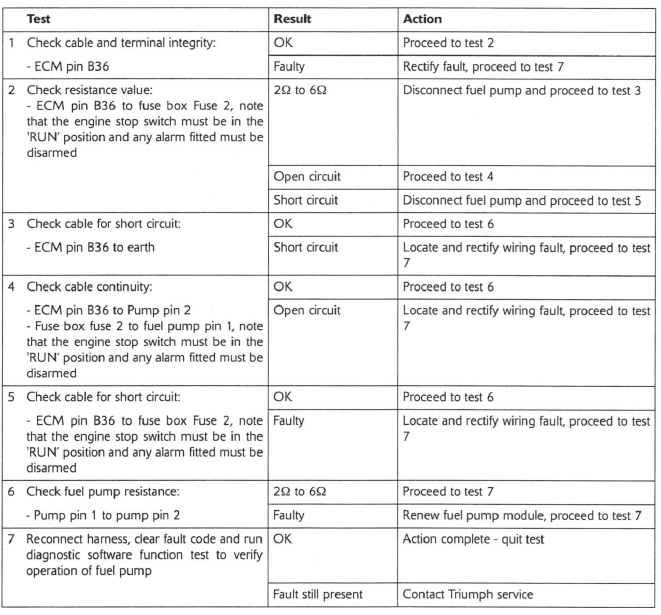

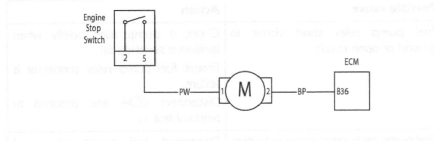

Fuel Pump - up to VIN 300525 - without Fuel Pump Relay

Pinpoint Tests

Circuit Diagram

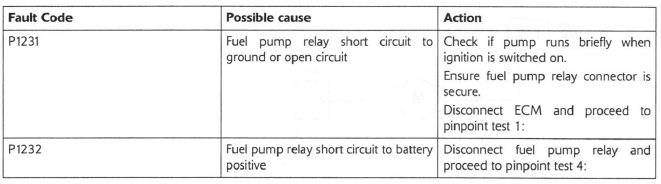

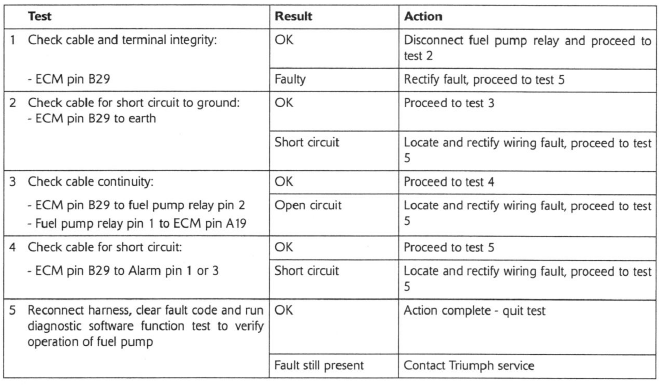

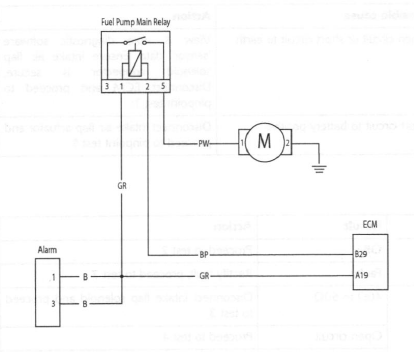

Fuel Pump - from VIN 300526 - with Fuel Pump Relay

Pinpoint Tests

Circuit Diagram

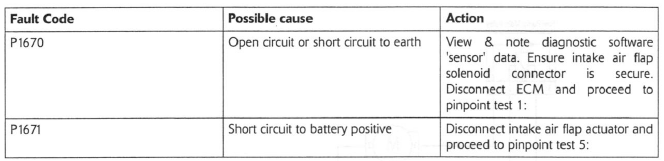

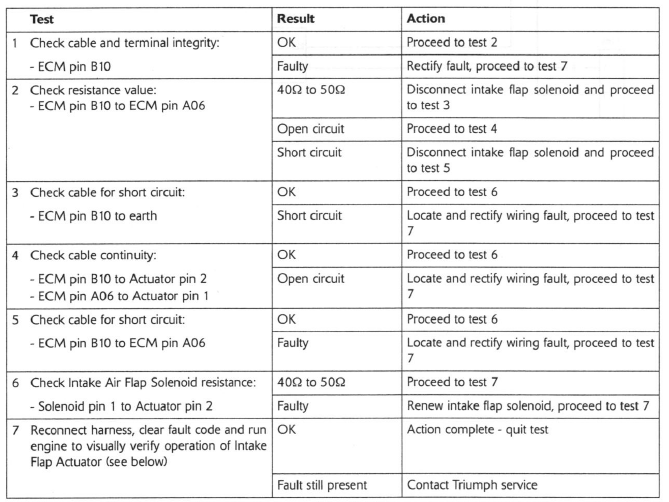

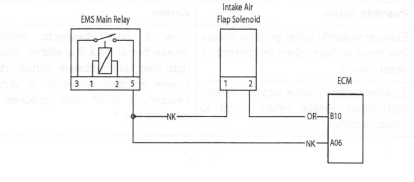

Intake Air Flap Solenoid - Daytona 675 only

Pinpoint Tests

Note:

- To verify the correct operation of the air intake flap, start the engine and briefly raise the engine speed above 4500 rpm. The flap should be seen to open as the engine speed rises and close again as the engine speed falls.

Circuit Diagram

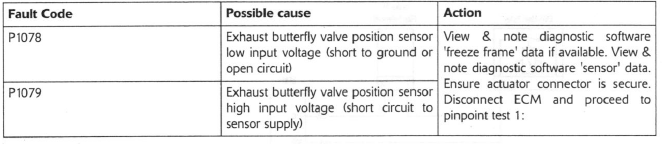

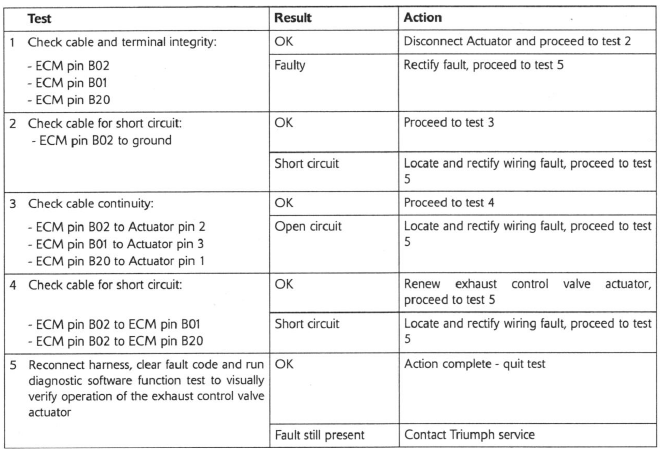

Exhaust Butterfly Valve (EXBV) Position Sensor - Daytona 675 only

Pinpoint Tests

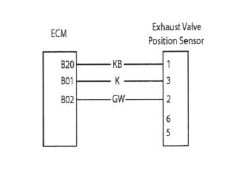

Circuit Diagram

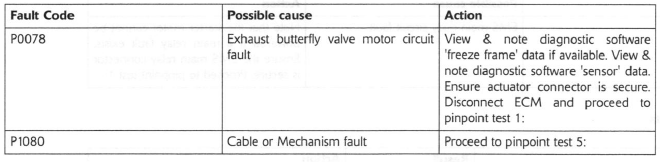

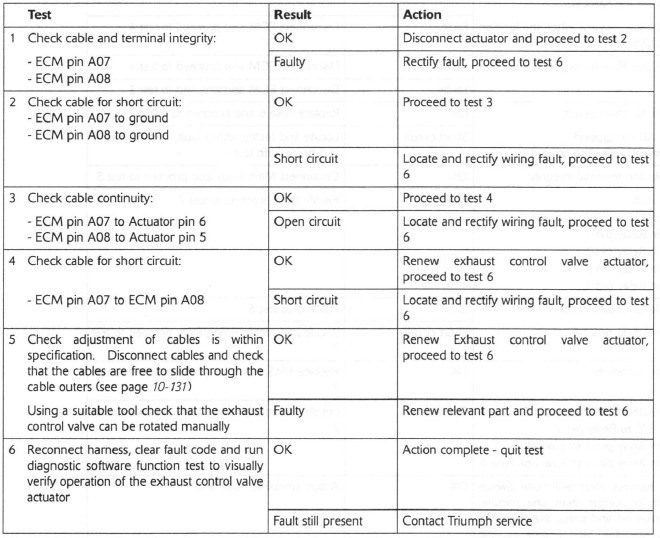

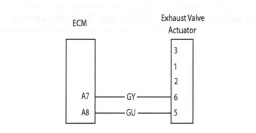

Exhaust Butterfly Valve (EXBV) Motor - Daytona 675 only

Pinpoint Tests

Circuit Diagram

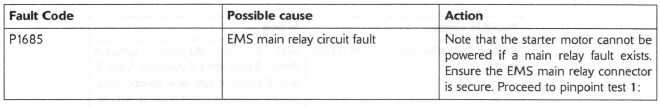

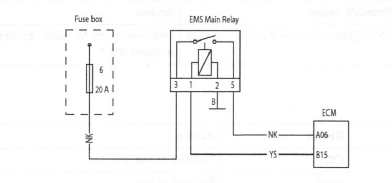

EMS Main Relay Circuit

Pinpoint Tests

Circuit Diagram

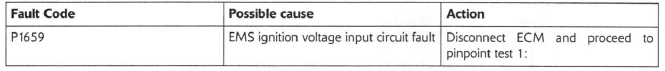

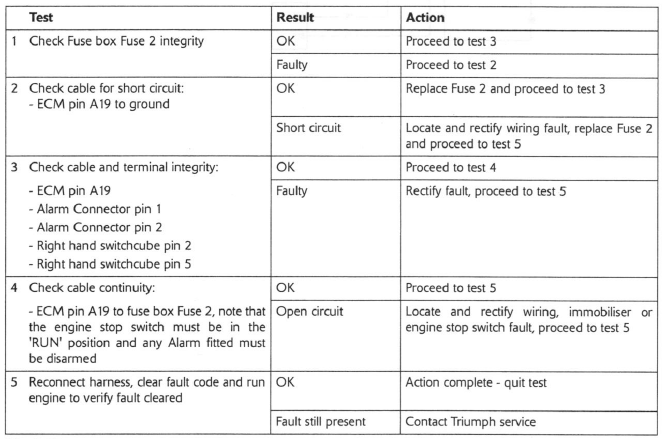

EMS Ignition Voltage Input Circuit

Pinpoint Tests

Circuit Diagram

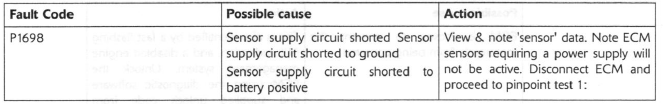

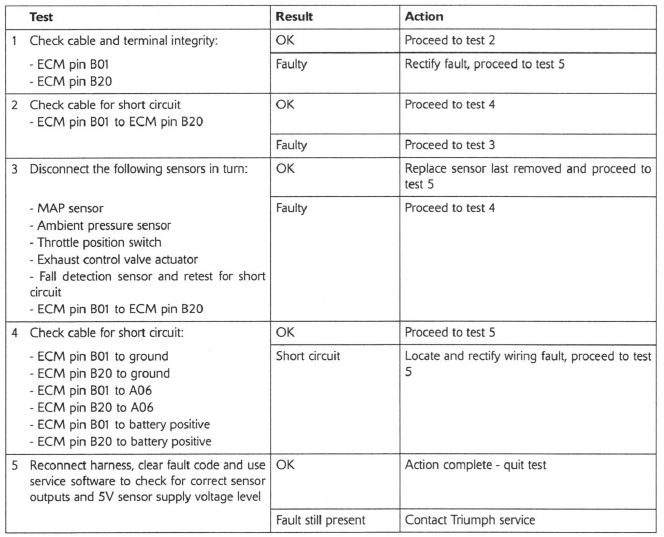

5 Volt Sensor Supply Circuit

Pinpoint Tests

Circuit Diagram

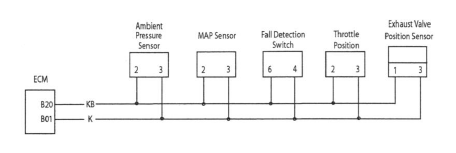

Tune Lock

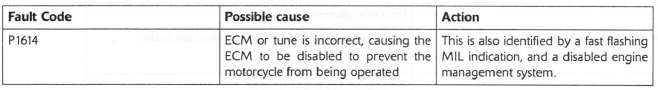

ECM or Tune ID Incorrect

Pinpoint Tests

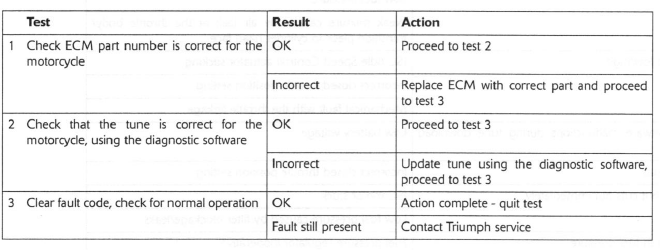

Fault Finding - Non Electrical

See also:

Triumph Street Triple S - Service manual > System Diagnostics

Triumph Street Triple S - Service manual > System Diagnostics

The engine management system has an on-board diagnostics feature which allows service technicians to retrieve stored data from the ECM using the Triumph diagnostic software. Full details of the Triumph diagnostic software operation and how to interpret the results are given in the Triumph Diagnostic Tool User Guide.

Triumph Street Triple S - Service manual > Fuel Tank

Triumph Street Triple S - Service manual > Fuel Tank

Removal Warning: Observe the warning advice given in the general information section on the safe handling of fuel and fuel containers. A fire, causing personal injury and damage to property, could result from spilled fuel or fuel not handled or stored correctly.

Benelli Imperiale 400

Benelli Imperiale 400 BMW F900XR

BMW F900XR Honda CB500X

Honda CB500X KTM 390 Adventure

KTM 390 Adventure Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03 Kawasaki Z400

Kawasaki Z400 Triumph Street Triple S

Triumph Street Triple S Yamaha MT-03

Yamaha MT-03